A flexible production revolution in 200 garment factories, a major change in Chinese manufacturing!

A flexible revolution broke out in 200 garment factories one after another, and the person who lit the fuse was called Bison.

He spent five whole years doing this. Bison said he hoped the war would burn more fiercely, and it would be better to wrap up all the good factories in China.

Bison knows that industrial Internet is a new round of global major historical opportunity after the consumer Internet. And flexible production is the "seven inches" of industrial Internet. He used the C2M platform model as a fuse. Perhaps, a small step of his own desperation can start a big step forward for Chinese manufacturing, when it is difficult, he uses this phrase to give himself strength.

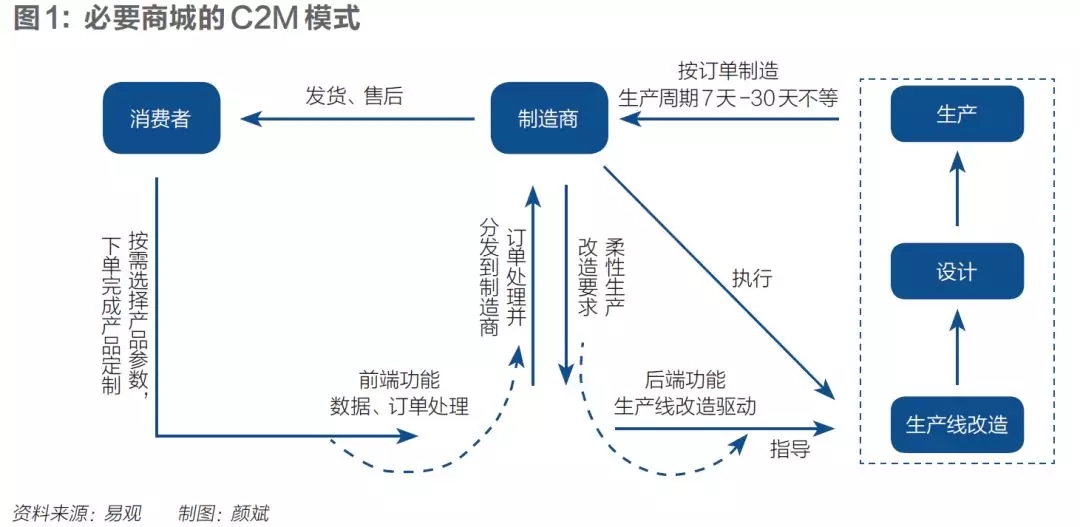

What is C2M model?

What is the C2M model? C refers to the consumer, M refers to the manufacturer of the big brand OEM, Bi Sheng founded the necessary is to connect the two, in the sales channel to the M side at the same time, the C-side data also synchronized to it, so that not only through the manufacturer of long-term OEM difficult to create their own brand pain points, but also crack it can not directly reach the consumer difficulties.

What's more, the C-side data will force the M-side to transform the production line flexibly, and the flexible revolution will be triggered from. This is exactly what the international brands dream of, it responds to the market demand.

Sounds beautiful, is it so?

M-end sniffs out the consumer

An hour's drive east from the campus of Asia's largest jeans manufacturer, Baofar Textile & Apparel, is the headquarters of Gree Electric. "Next door to us is Gree Electric", as Baofa's product director Luo Hongwei always introduces, envious of Gree's brand power.

Asia's leading jeans manufacturer and chairman of Baofa Textile & Apparel, Yongqiang Zhong

Yongqiang Zhong is the chairman of Baofa, who started his business in 1992 and moved his factory from Macau to Jiangmen, Guangdong in 2005. The 150-acre campus supports the production of jeans for Calvin Klein, Diesel, Levi's and other famous brands. He has been trying to launch his own brand, first with an online store and then with five offline stores in Beijing, all of which ended in failure.

In 2015, less than a year after the creation of the C2M model innovation Necessary Mall, founder Bison invited Zhong Yongqiang to open a store on Necessary Mall. "Big brand quality, factory price" was the signature phrase of Necessity, and what attracted Yongqiang Zhong. He launched the Timeable brand and became one of the first four factories to set up shop in Necessity Mall.

Zhong Yongqiang soon experienced the difference. In the past, when they were OEMs for big brands, they just produced, but now they not only produce jeans according to the shape of Chinese consumers, but also keep creating pop-ups. "We've never really smelled the consumers like we do now." Luo Hongwei said.

In 2018, Baofa's sales on Necessity Mall reached more than 30 million yuan, a small percentage of its total revenue of 600 million yuan, but it has grown by more than 20 percent every year since 2015.

At present, the necessary mall of goods involved in a total of 25 industries, many of which have a common point, that is, the production side and the consumer side between the links, the bulk of profits taken by the intermediate links. Therefore, the necessary mall partner Cheng Jianyong choose the industry and cooperation factory, the key to see how much intermediate links can be eliminated, because this determines the profit space for manufacturers and consumers.

The eyewear industry is extremely typical. In the optical store, a pair of myopic glasses cost thousands of dollars, which is seriously off the cost. In early 2015, Bison approached Vision Optical and invited it to join the necessary shopping mall. Vision Optical is the lens provider of France Essilor, the world's largest eyewear company, and Danyang, Jiangsu province, is the lens capital of China, where 50% of the world's lenses and 80% of China's lenses come from.

Being used to OEM, Vision Vision didn't like it, but eventually Bison's visits again and again moved Wang Xiangyu, the 80-year-old "young boss" of Vision Vision Vision. They joined forces to set up a must see technology, for the necessary customers to create the "necessarily" brand.

"Necessarily" myopia glasses in the necessary only sold 169 yuan, but if in the opticians have to sell more than 600 yuan, if the brand price is more than 2000 yuan, but they are all produced by the vision Yue, the cost of quality is the same.

Because of the high quality and low price, the growth of Bespoke is fast. 2018, Bespoke's page conversion rate on the necessary has risen to 10%, the repurchase rate reached 48%, and sales revenue exceeded 40 million, accounting for 8% of the total revenue of Visionary, and this year is expected to reach 80 million yuan. Wang Panpan, CEO of Essential Look, said that in just four years, Essential Look's sales have matched those of Chiba Optical, which was founded in 1992 and is the largest optical store chain in the southwest with more than 300 physical stores.

How difficult is the flexibility revolution

Unlike Visionjoy, many industries need to flexibly modify their production lines to meet the necessary orders, which is tantamount to a revolution for manufacturers who are used to high-volume orders.

Flexible production is not a new concept, invented by Ford Motor Company in the 1920s.

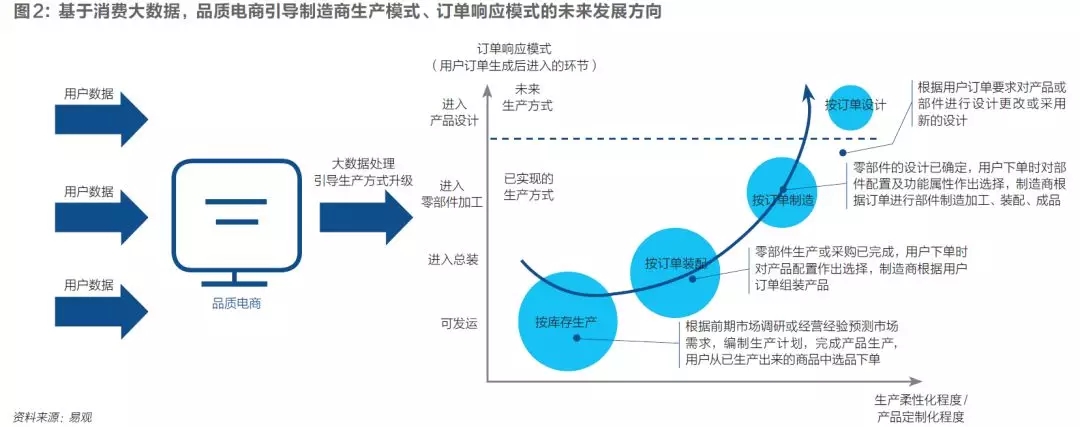

In fact, at the time of the necessary birth, consumer demand for personalized small batch has been on the rise. 2015, Zhong Yongqiang found that the total number of orders of big brands is not less, but the orders are getting smaller and smaller - 100,000 pieces of large orders are missing, 3,000 pieces are already considered large orders, more are a few hundred pieces or even smaller orders. "Small single fast return" has become the trend.

Bison is more perceptive by the e-commerce immersion. Small single fast return, the most direct challenge is how to deal with inventory, when the brand to the inventory pressure upward conduction, the production side there is no way to eliminate inventory?

First production and then sales, inventory can not be avoided; but on the contrary, the first order and then production, that is, C2M model, can achieve zero inventory. After thinking clearly, in 2014, Bison sold his B2C e-commerce company and founded a new e-commerce platform in C2M mode, Necessity Mall.

Bison's calculation is, necessary to low transaction commission to attract big brand OEM factories to station, with big brand OEM manufacturing quality to attract consumer upgrading people to order, and then the necessary orders on the precise delivery to the manufacturing factory to sell production, to help it eliminate inventory, the best of all three worlds.

The ideal is very rich, the reality is very skeletal. Bison spent 17 months, flying hundreds of thousands of kilometers, drinking hundreds of pounds of liquor before recruiting the first four manufacturers to station.

The challenge is even greater after the arrival. Bison and the foundry need to face is, how to change from the habit of receiving 10,000 or 20,000 orders at a time, with a month or two to production to the mode of receiving 30 or 50 orders at a time and doing it in a few days?

Baofa began to experiment. The good thing is that they have been on the ERP system in 2005, a little adjustment can be connected with the necessary mall backstage data, according to the real-time adjustment of production tasks. However, when the order keeps changing hours, how to prevent the cost from rising due to the decline of scale efficiency?

Smart Zhong Yongqiang did not spend a lot of money on intelligent upgrading, but relied on flexible production lines to pinpoint the balance between flexibility and standardization. For example, he turned the original 80-person, 100-meter-long monogram production line into a 20-person, 15-meter-long U-shaped production line, so that the total process did not change, but the workers changed from doing one process to doing four processes, which significantly reduced production costs.

Hanpai Group, China's largest women's apparel manufacturer, is a different story.

In 2016, Gao Min decided to cooperate with Necessity, and the hard battle of flexible production came immediately.

In the past and H&M, Zara, MaxMara and other big brands, Hanpai's order delivery period is mostly in a month and a half to three months, necessary on the order delivery cycle is 7 to 10 days, and every day to collect new orders to set production. Hanpai's products are dresses, coats, jackets, light version of the H, X, A type and more than a dozen, variable version, small orders, the challenge of flexible production is evident.

"No one wants to be the factory manager, so I'll do it myself." Hanpai Group is responsible for intelligent manufacturing business Wu Qiaohui recalls, "every month there are team leaders to mention the departure, the new way of working is really broken."

"The key to flexible capacity is in the people, otherwise the high level of equipment is useless." Gao Min said. Flexible production is actually process re-engineering, people, machines (machines), materials (materials) recombination. On a traditional production line, the position of the machine and workers is fixed, and each person is responsible for a fixed process; on a flexible production line, the machine does not move, and workers move according to the instructions and processes on the PAD, taking care of multiple processes and increasing the space available for play.

The main equipment of the garment factory is the sewing machine, Hanpai has 10,000 sewing machines, if all replaced with the latest CNC sewing machines, it requires an investment of more than 100 million yuan. They chose to retrofit the old machines by laying a gateway network cable to connect the sewing machines to the network, then installing sensors under the sewing machines to collect data, and installing PADs on the sewing machines to display the data. The retrofitting cost plus the operation and maintenance cost is only 1600 RMB a year for one machine to achieve the effect of CNC sewing machine.

Coordinating the workers' flexible work is an intelligent device attached to the sewing machine, which presents production instructions and process steps for all garment styles on a display.

After two years of break-in, Hanpai workers have fully adapted to the C2M model and can quickly complete orders of as few as 50 pieces.

"All changed back in a year." Gao Min was surprised to find that many big brands are looking for flexible supply chains, and orders that once went to Southeast Asia are starting to flow back.

Because of the flexible production change, in 2018 Gao Min was invited to enter the H&M strategic advisory group consisting of six core suppliers around the world, after 27 years of cooperation with H&M, H&M's management has never been in this advisory group. "More important than that is the possibility to explore the C2M2C model with the necessary." Gao Min said.

Electronic signage on the production line of essential mall supplier Hampo Group

People-driven production platform

Bison doesn't like to be called an e-commerce company, but he believes that Necessity Mall is a "people-driven production platform". People is the consumer, he through the necessary platform to pass the demand to quality manufacturers, drive their flexible production, manufacturers and then provide quality goods to consumers.

"Five years, we have done one thing: the big brand quality with factory prices to consumers", Bison said.

From the price point of view, the necessary mall on the goods using the cost pricing method, commodity prices = BOM price (raw materials, labor, process) + logistics costs + factory gross profit + platform deduction points, of which, the platform deduction points for the sale price of 2% to 15% ranging, the mall on the goods according to the user evaluation sort, do not engage in bidding ranking, factory entry costs less than 40% of the big e-commerce platform.

From the quality point of view, there are two necessary moves. First, the necessary mall will control the suppliers of each category in 2 to 3, compared with Tmall, Jingdong and other platforms with millions of sellers, the necessary suppliers do not need to bother with promotions, just concentrate on good products.

Second, with other boutique e-commerce build their own huge quality control team quality of goods but repeatedly out of control different, necessary to take the "control of the two ends, let go of the middle" of the quality control strategy. One end is the entrance, the manufacturers must meet 56 criteria, including "must have served international first-line brands", "must have independent product development and design capabilities", etc., any one does not meet, you can not be in the necessary mall; the other end is the export, that is Consumers, on the necessary where the poor rating rate of more than 0.75% of the goods, will be forced off the shelves.

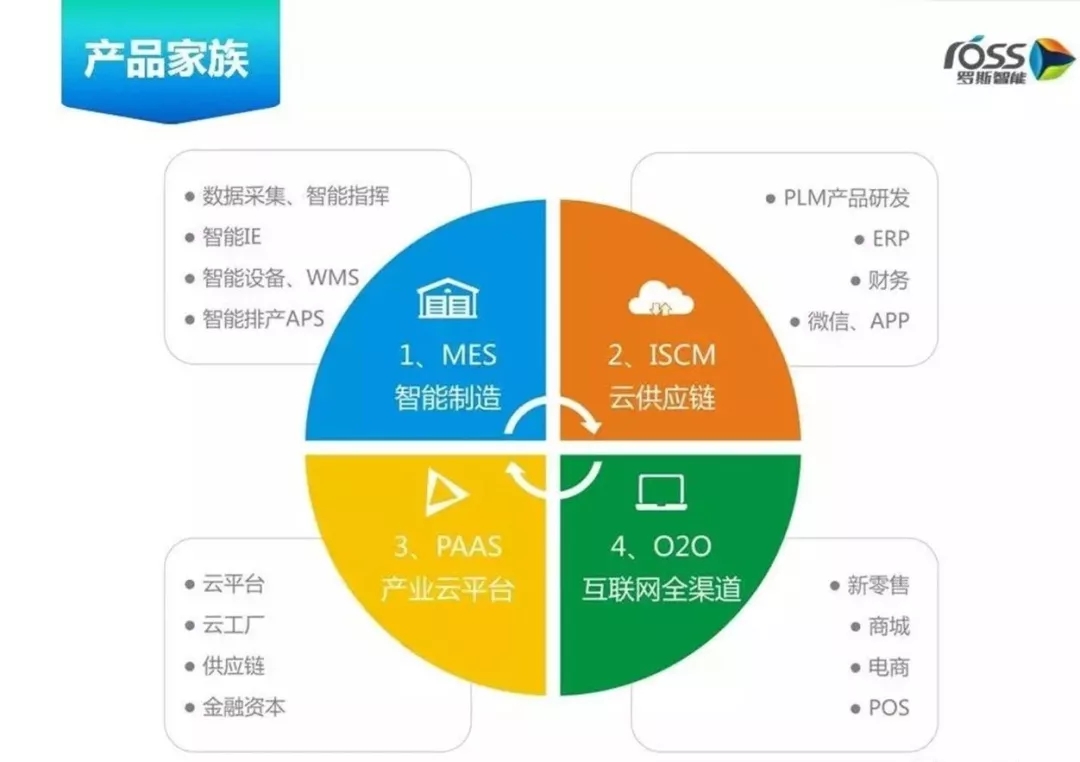

Release the middle, referring to the release of the production chain to the manufacturer. "I can't know how to make jeans better than Lao Zhong (Yongqiang)," Bisson said, but Necessity can explore the optimization of the production process with factories, reconfigure the interests of factories and channels through target management and the intelligent cloud manufacturing system developed by itself, and promote factories to refine linear management to modular management to achieve flexible production steps jump and improve production accuracy.

Like Jiangmen Baofa, Danyang Suyue, Hangzhou Hanpao, 200 large Chinese factories that had long been hidden behind the big international brands with high quality manufacturing capabilities are being changed course by a flexible revolution triggered by the necessary mall with the C2M model. The necessary model not only provides new possibilities for manufacturing enterprises, but also gives new development ideas for the giant e-commerce industry.

The C2M model is flourishing in the context of the industrial Internet. The core of the Industrial Internet is to connect people, data and machines, combining software and big data analysis to reconfigure the industrial structure and bring unprecedented solutions to manufacturers and customers.

This year's government work report points out that building the Industrial Internet and expanding Smart+ will empower the transformation of the manufacturing industry. According to preliminary statistics from the world's second largest market research firm , the global market for industrial internet platforms was approximately $3.27 billion in 2018, with an average growth rate expected to exceed 33% over the next five years.

The spring of C2M has just begun. "But if you do the right thing, you will be rewarded with good things." Bison said.